Products

hot products

Contact Us

Shandong Chinsail Machinery Co.,Ltd

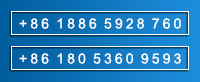

Tele: +86-0536-2087685 / +86 180 5360 9593

Whatsapp / Mobile: +86 1886 5928 760

Skype: +86 1886 5928 760

Email: info@chinsailcnc.com

Address: Room 1703, Century Global Center, Xinhua road No. 1589, Kuiwen district, Weifang city, Shandong province

Cnc router

fiber laser cutting machine CXF1530-1500W

2025-12-23 views:If you have any questions, pls feel free to contact me: Email: info@chinsailcnc.com Tele: +86-0536-2087685 /+86 1805360 9593

Whatsapp / Mobile: +86 18865928760 Skype: +86 18865928760

No.1 Features of cnc fiber laser cutting 1500w (also have other power to choose)

1. Compare with the plasma cutting, it has the high precision cutting for different kinds of metal materials,

like cutting stainless steel, carbon steel, alloy steel, spring steel, aluminum, copper, silver, titanium and other metal

materials below 6 mm.

2. Compare with the NC, which can cut any complicated process and shape.No noise and no need to open any moulds at all.

3. Compare with linear cutting, which has much faster speed,100 times higher than it.

4. Double lead screw to drive, Small heat affected zone, good dimension stability. Flat and handsome laser-slotted,

without later process

5. High performance/price ratio: the price is only 1/8 of the similar CO2 laser cutting machine and 2/5 of the equivalent

NC Punch

6. Low use cost: only USD2 per hour which is 1/8-1/10 of the similar CO2 laser cutting machine (USD22-USD35 per hour)

7. Low follow-up maintenance cost: only 1/10-1/15 of the similar CO2 laser cutting machine and 1/3-1/4 the equivalent

NC Punch

8. Steady performance: as a mature laser apparatus, the Fiber laser cutting machine is suitable for most metal

manufacturing and processing industry.

No.2 Application

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet,

pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile,

machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts,

tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

No.3 Parameters

| Working area | 1300*2500mm/1500*3000mm option |

| Control System | Au3tech control system |

| Laser head | Au3tech cutting head |

| Guide rail | Taiwan HIWIN linear guide rail 25mm |

| Transmission | Taiwan TBI ball screw transmission/Gear rack transmission option |

| Electronic Components | Taiwan Airtac pneumatic element |

| Motor | Japanese YASKAWA servo motor/Taiwan Delta servo |

| Max Cutting Speed | 50m/min |

| X axis max speed | 65m/min |

| Y axis max speed | 100m/min |

| Z axis max speed | 30m/min |

| X axis max acceleration | 1G |

| Y axis max acceleration | 1G |

| Cooling Way | Water Cooling |

| Min line width | 0.1mm |

| Power Requirements | 380V, 50/60Hz, 16A |

| Continuous Working Time | 24Hours |

| Machine body | 1300*2500mm working area | 1 set |

| Laser generator | Standard | 1 set |

| Water chiller | cooling laser head and generator | 1 set |

| Control box | Cypcut control system | 1 set |

| Laser cutting head | Auto following function | 1 set |

| Protective lens | standard | 1 pc |

| Focus lens | standard | 1 set (2 pcs) |

| Consumable parts of cnc fiber laser cutting machine 500w | |||

| Name |

Use life |

Price(USD) |

Suggested quantity |

| Protective lens | 600 hours | 60/pc | 5 pcs |

| Focus lens | 600 hours | 650/set | 2 sets |

| Nozzle | 600 hours | 20/pc | 10 pcs |

No.4 Advantages

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine

have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption,

it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy operations: fiber line transmission, no adjustment of optical path.

No.5 After sale service

1. 24 months guarantee of the whole machine.

2. Main parts(excluding the consumables) shall be changed free of charge if there is any problem duringthe warranty period.

3.Lifetime maintenance free of charge.

4.We will provide the consumable parts at a factory price when you need replacement.

5.Machine has been adjusted before delivery.

6.Our technician can be sent to your company to install or calibrate if necessary.

No.6 Related models : CXF1530-1500W 2000W 3000W 4000W 6000W 8000W 12000W 20000W etc.